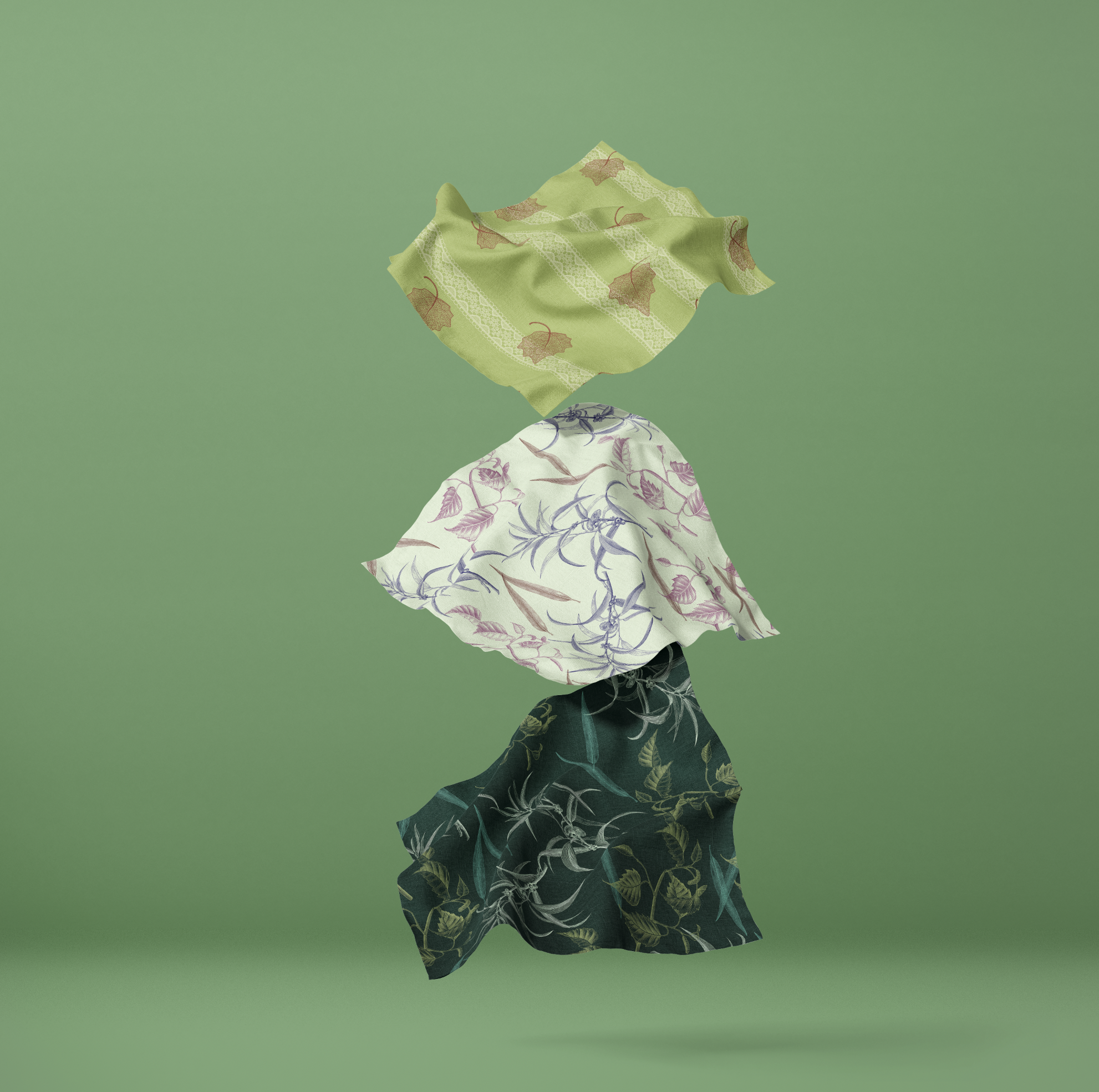

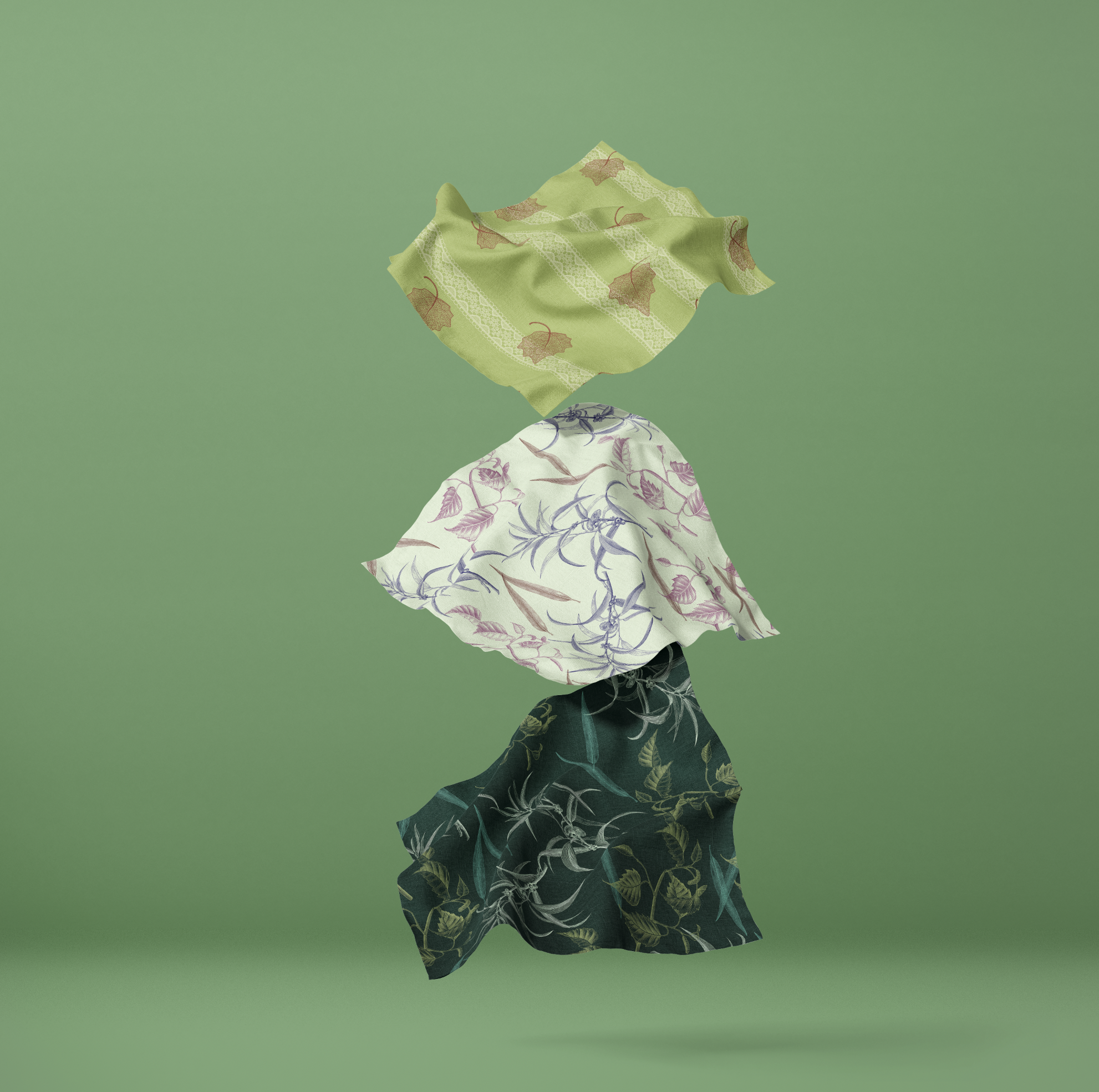

Digital Reactive Jersey 230

230 GSM, 150 cm wide

Reactive printing is like the precision artist of fabric printing, while pigment printing is more of a versatile all-rounder. With reactive printing, a special ink layer—made of reactive dyes, a binder, and heat-activated additives—is steamed and washed to lock in its magic. The result? Vibrant, deeply embedded colors that are super durable and perfect for cotton garments.

The process relies on heat to create those eye-popping, long-lasting prints, making reactive printing a popular choice for designers chasing bold and rich results. However, it’s not a one-size-fits-all solution. While reactive printing excels at vibrant and wash-resistant designs, pigment inks shine with their simplicity and flexibility, working well on a variety of fabrics with minimal fuss.

So, reactive printing isn’t “better” than pigment—it’s just a different approach, each with its own strengths depending on the look and purpose you’re going for!

Reactive printing shines brightest (ironically!) when it comes to achieving darker and deeper colors. Its ability to bond directly with the fabric fibers ensures rich, saturated hues that truly pop. This makes it the go-to choice for designs that demand bold, intense shades that last.

We need to outsource reactive printing, which adds to the production timeline. This is why there’s typically a lead time of 4-6 weeks for projects using this technique.

While the results are stunning, the added time ensures the process is handled with the expertise and care it requires!

Specifications

Qualities

Care instructions